Our Process.

DESIGN IT.

For our projects we start with 3D CAD process - creating a digital model using Matrix Gold - specialist jewellery software. This model is designed using our experience of production tolerances, something a lot of people overlook to make sure it can be made perfectly in bulk. This model is then used to produce a physical prototype using state of the art 3DS Printers, ensuring micron precision and enabling efficient mass production of a final jewellry piece.

MAKE IT.

For most projects we use the lost wax process to create a high detailed mould of a fully finished metal cast. From that mould we inject wax to make copies and do the whole process again, melting the wax away, and pouring molten metal into the mould to produce intricate, high-quality pieces.

If the project calls for other processes such as laser cutting we have full capabilities to produce any type of item.

SELL IT.

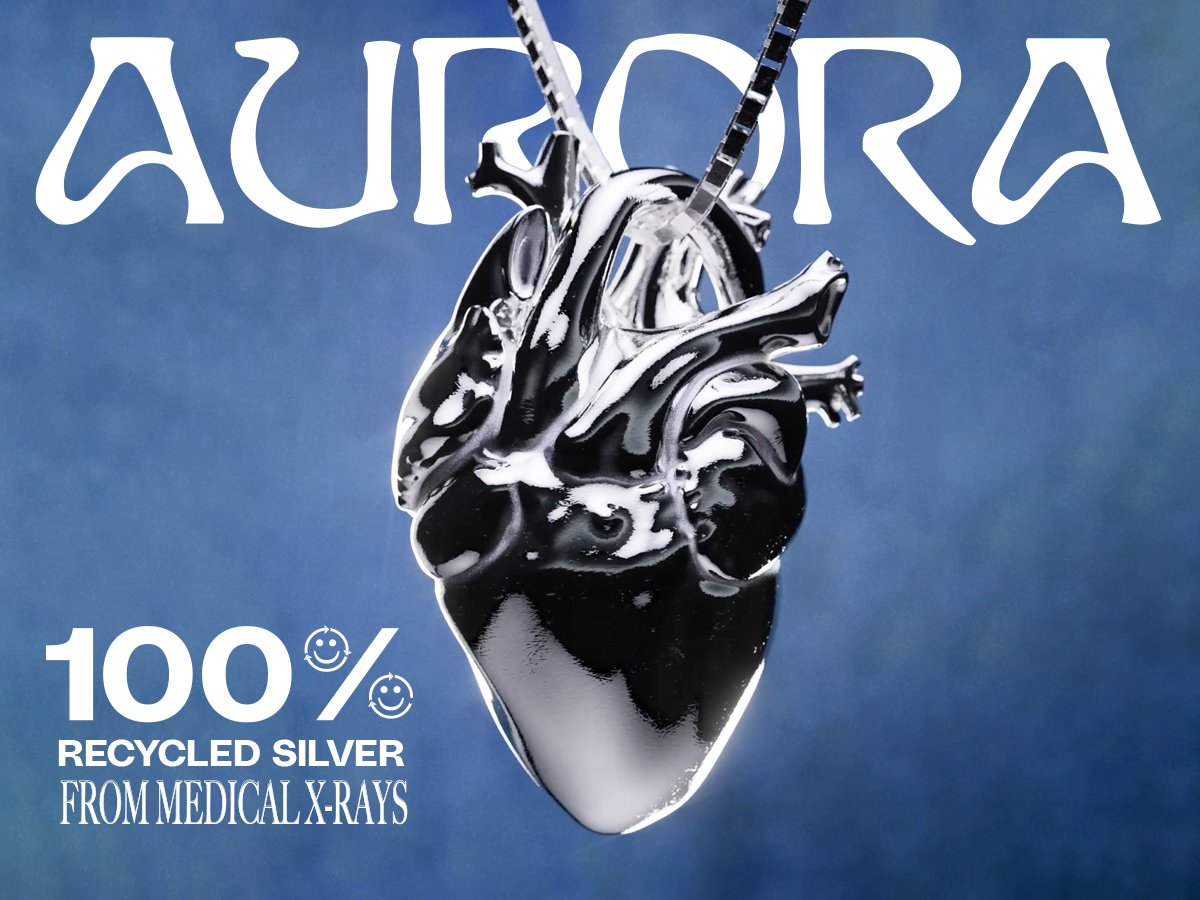

The power of visuals, marketing & branding cannot be overstated - as a full service company not only do we help your business make incredible jewellery, we can help you sell it too. Not only can we sort all packaging, barcoding and bagging, we offer 3D content which can be used to presell items or be used for marketing materials, professional photography for perfect product shots, and a suite of graphic design options to dramatically elevate your product.